Your expectations are high – our standards even higher

Industrial PCs must provide maximum performance under the most adverse conditions, so the expectations of our customers and the requirements on our BEGits are correspondingly high. Our BEG standards are designed to meet – and exceed – these expectations and requirements.

Series delivery

We typically collaborate on the basis of a framework order. This enables us to achieve price stability and high supply capability combined with short delivery times.

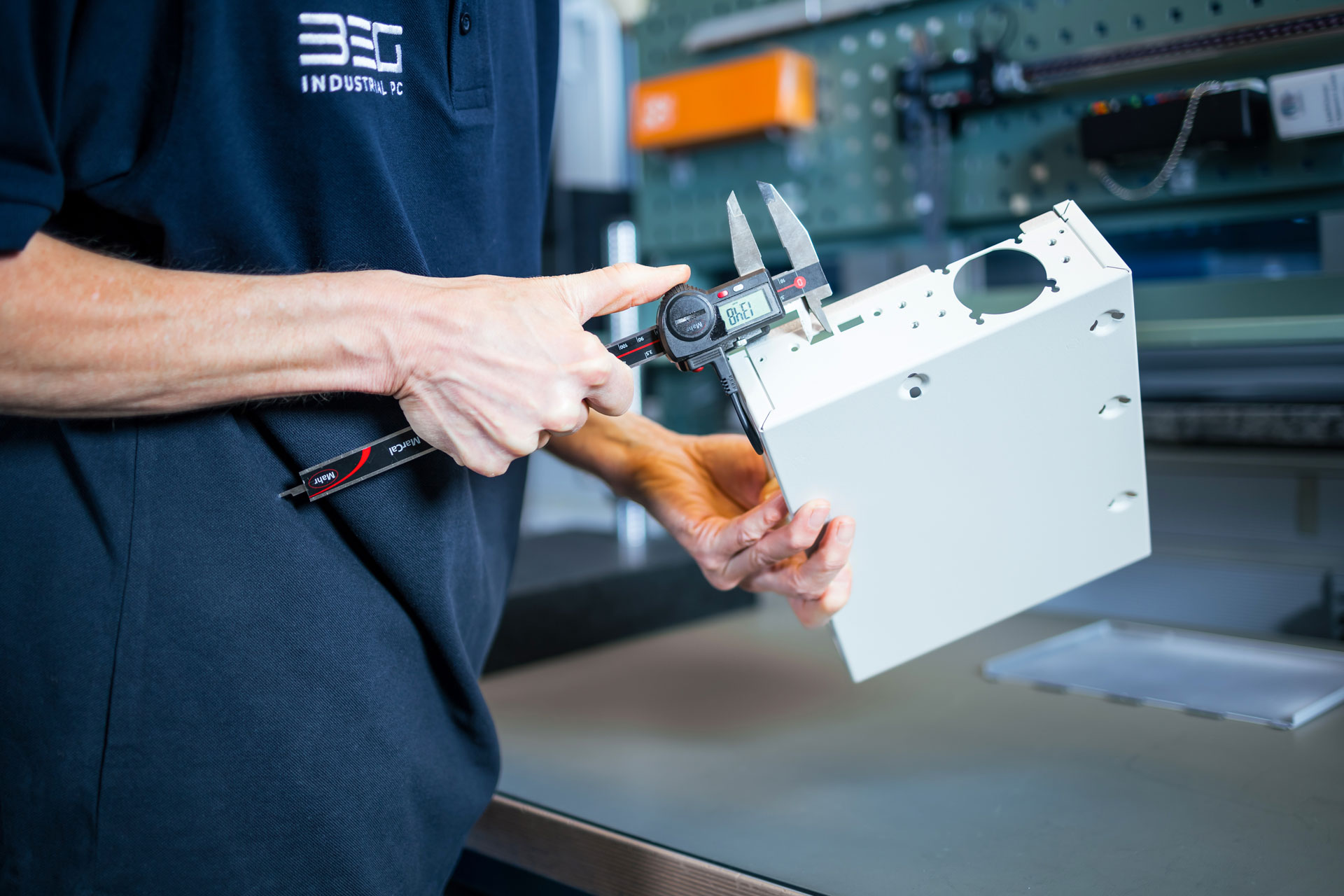

Incoming goods inspection and inspection for all delivered goods

Additional quality inspection:

- For all drawing parts or critical components in each predefined sample

- For each delivery lot

- 100% for initial samples at the start of a series production

- Through serial number entry using ERP for all serial number-managed components

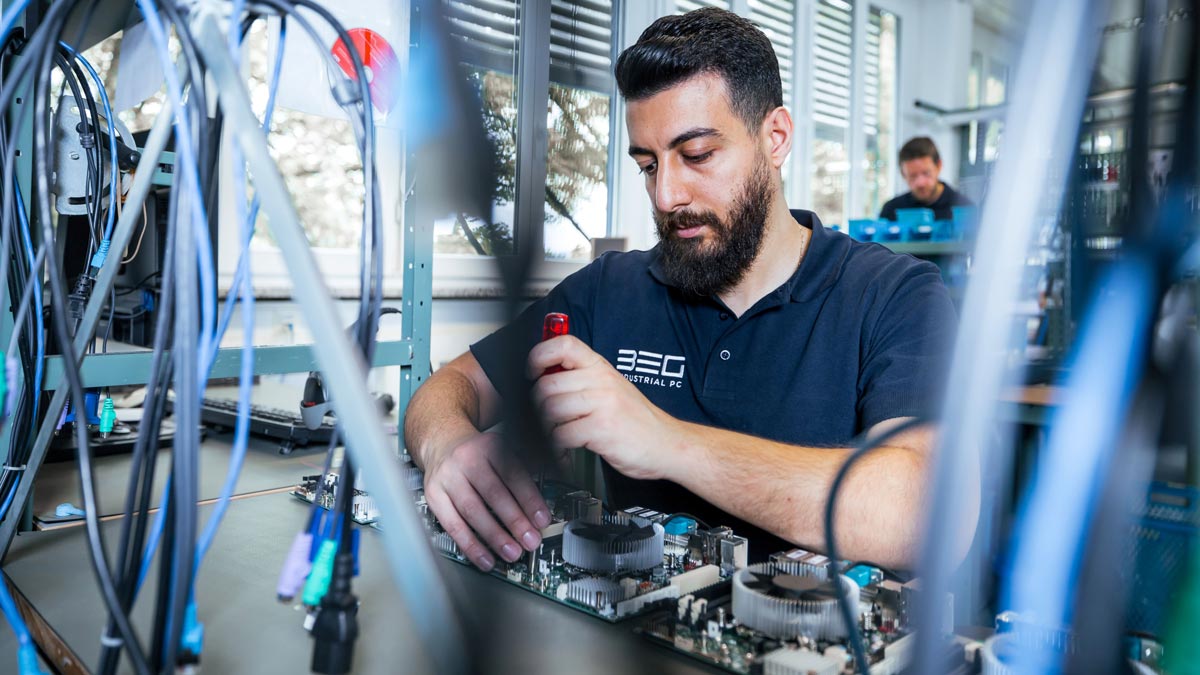

Production process

- Devices are merged in economically and procedurally reasonable batch sizes. Each device is given a unique serial number in order to achieve clear traceability for the elementary individual components (traceability).

- Initial operation to check whether the computer boots or everything works at first glance. If the result is positive, the installation of the test software continues.

- With the 24-hour burn-in test at a maximum permissible operating temperature (50°C), we pre-age 100% of all BEGits so that early failures, which are standard for electronic components, occur in-house. This guarantees that our BEGits perform smoothly for our customers and their customers.

In conjunction with extensive testing software, the hardware undergoes intensive testing and, if the test is 100% successful, a test report is finally created. This includes the following components:

- Processor/CPU (CPU load test, stress test, cache test for L2 and L3 CPU cache, FPU, MMX, SSE, AVX etc.)

- Mainboard (PCI bus, CMOS RAM/real-time clock, hardware monitoring)

- Memory/RAM test (7 different memory tests, SPD EEPROM information for the RAM modules)

- Hard disk tests (mechanical test & access time, fast read benchmark, read test with instruction duration analysis, write test, SSD SMART and NVMe SMART and many more)

- Graphics cards (test images, memory tests, 3D benchmark, GPU computer stress test, GPU calculation benchmark, graphics card stress test)

- Speaker/sound (audio input and output)

- Interfaces such as USB in all common speeds (1.1 to 3.x), COM (232&485) and LPT

Electrical safety testing

The legally required measurements according to the EC Low Voltage Directive 2006/95/EC are carried out and logged for all AC devices.

Final inspection

We perform visual, mechanical and electrical inspections, and we check whether all defined tests have been carried out. In addition, we check the customer-specific image installations and, if necessary, optional customer-specific tests are carried out in order to simulate the customer installation in-house.

Standard in the development process

When developing our BEGits, we either proceed according to specifications or develop a system concept with component selection. When selecting components, we pay attention to a sustainable system concept that is available in the long term, which ensures an extremely robust and reliable computer. This ensures minimal change effort, combined with long-term image compatibility.

Different additional requirements for the shipment of our products

We have a warehouse to ensure short-term availability. We pay attention to pendulum packaging in order to avoid unnecessary waste as far as possible. Our parcel and logistics service providers ensure affordable, undamaged and punctual transport. We also use customer packaging on request.